GSP products covered over 90% of the worldwide automotive market. Supplying shock absorbers for the majority vehicles, including US, European, and Asian cars, SUV, HEV, and EV.

Over 7,000 SKUs

Various welding techniques, including resistance seam welding and CO2 shielded welding, were used to enhance safety.

Adopting high-pressure and high-temperature sealing technology to extend life cycle.

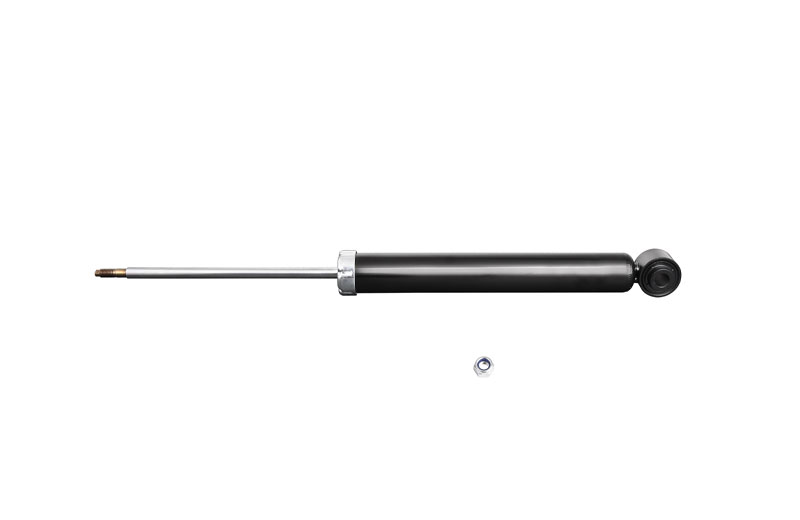

Hard chrome-plated shock absorber piston rod with high hardness and surface micro-cracks increase the durability and wearability of the oil seal. It also decreases the shock absorber rattling while in use.

Internal double barrel structure with high-performance working cylinder and oil to ensure durability over 4 million times without oil leakage and damping attenuation under the design standard.

GSP Shock Absorber filled with low-pressure nitrogen gas to eliminate the bubbling of the shock absorber fluid and reduce the empty range of resistance and discontinuity. It also improved the ride experience and performance of the vehicle under high-speed drive.

Designed to fit the local damping performance according to different regions of the country to meet the needs of users.